GROOVED

Processing grooves

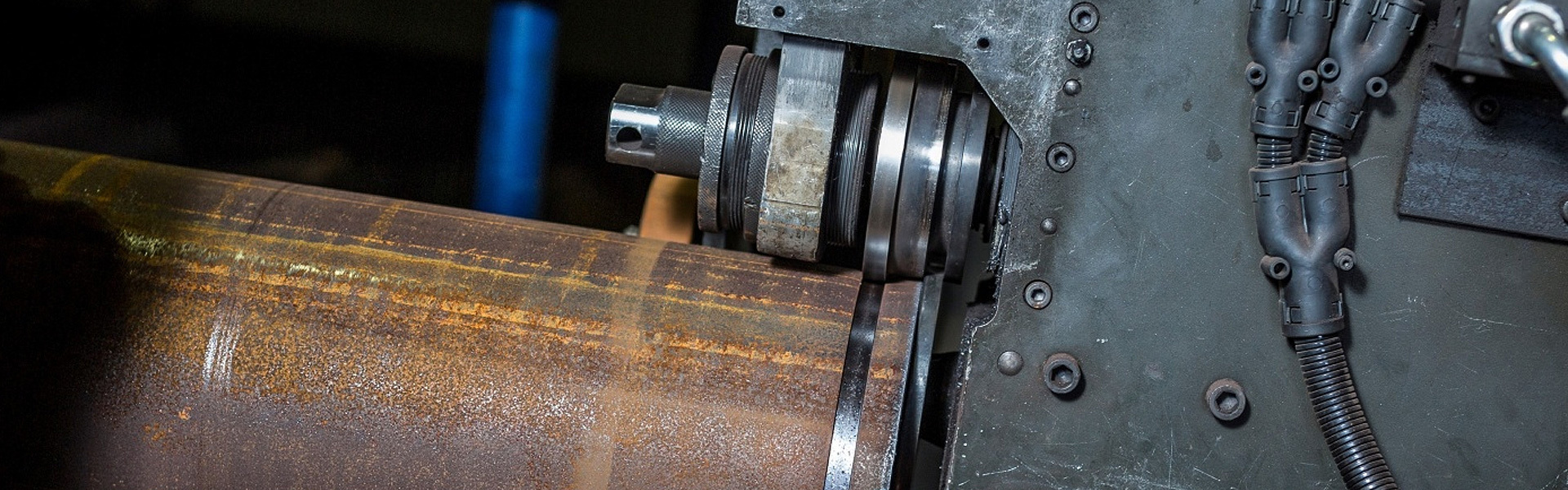

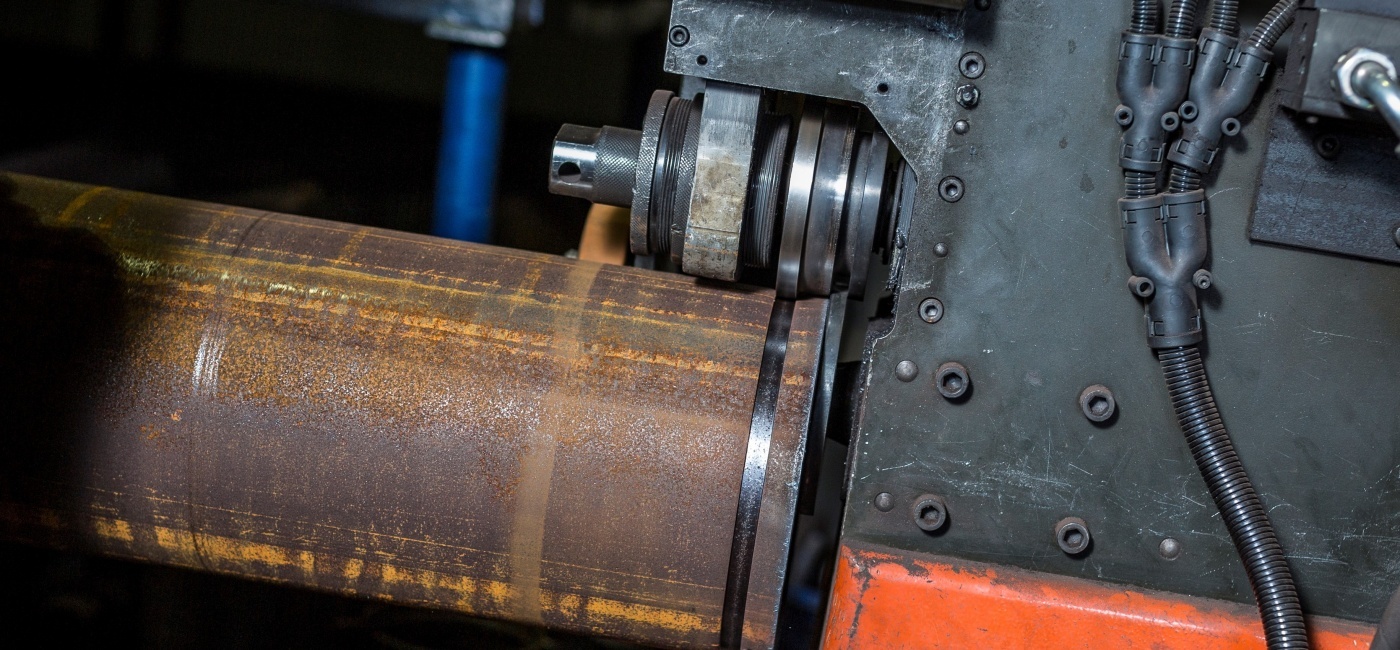

1. Use a cutting machine to cut the steel pipe on demand, and the incision should be flat.

2. Set the steel pipe to be processed on the grooving machine.

3. Place a horizontal ruler on the steel pipe, and level it with a horizontal ruler to keep the steel pipe horizontal.

4. Attach the end face of the steel pipe to the end surface of the grooving machine, so that the central axis of the steel pipe is perpendicular to the end surface of the grooving machine.

5. Start the grooving machine, slowly press down the jack, and make the upper pressure wheel evenly roll the steel pipe to the set groove depth to stop.

6. Check the depth and width of the groove with a vernier caliper, confirm that it meets the standard requirements, remove the load from the jack, and take out the steel pipe.

GROOVED

GROOVED

GROOVED

GROOVED

CONTACT US

Cell phone: +86 13373379809

Postcode: 061000

Mailbox: czbqpipe@outlook.com

Address: Pipeline Base Center, Cangzhou City, Hebei Province, China

Cangzhou Boqiang Pipeline Co., Ltd.